-

Wood

Wood -

Briquettes

Briquettes

Boiler advantages:

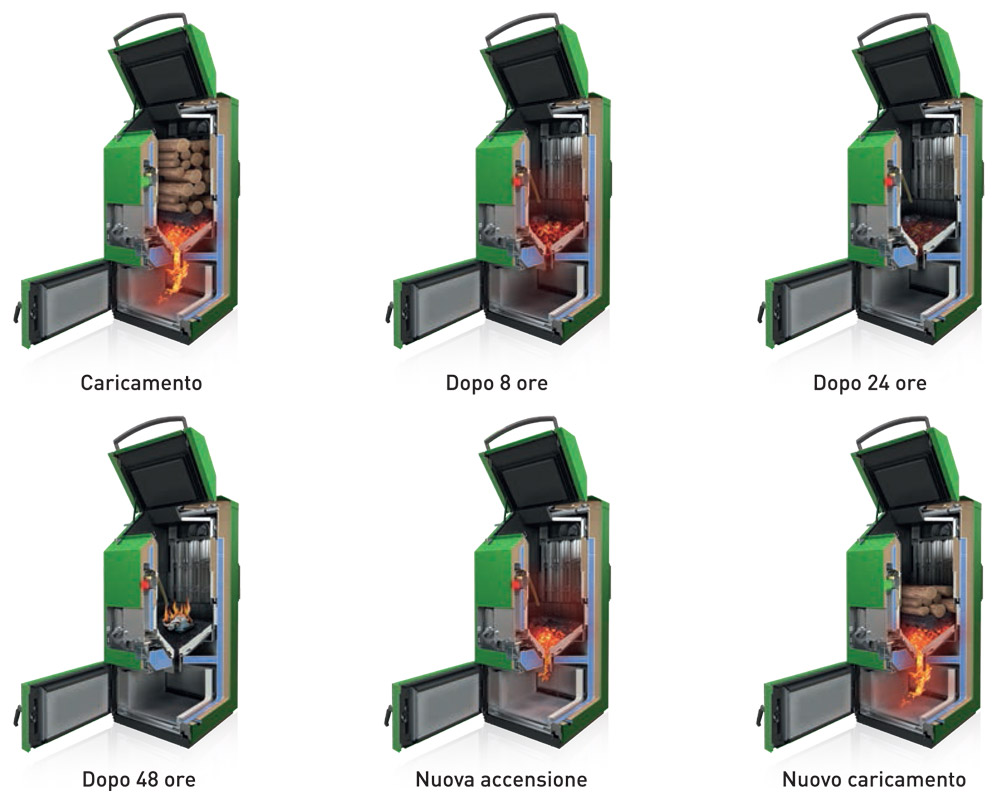

- Automatic ember maintenance system: the reduction beyond a certain limit of the fuel weight, due to progressive consumption, causes the fume extractor to switch off, maintaining a layer of embers in the combustion chamber for a few hours. In this way, the system exponentially reduces the number of cold starts of the boiler during a season. A quick restart of combustion, even with simple paper, is quick and easy.

- Integrated anticondensation system: equipped with protection against corrosion generated by the low temperature return fluid, it does not require the installation of additional external devices. An integrated thermostat with a pre-set temperature of 60° C and a mixing of the fluid in the boiler body guarantee the effectiveness of the anti-condensation system. A natural circulation hydraulic connection to the storage tank is possible, without the use of circulators. 5 year warranty on the boiler body.

- Dry combustion chamber: the walls of the combustion chamber are isolated, not in direct contact with the fluid, therefore reaching a very high temperature and preventing the formation of creosote. The average life of the boilers made with this innovative structure is considerably longer than that of the common gasification boilers. The boiler also allows you to burn a fuel with higher humidity, without significantly reducing its duration over time.

- Input with two primary air levels: ensures gradual and efficient combustion, located exclusively in the lower part of the chamber, and makes it possible to use fuel of various sizes and types (wood chips, sawdust, briquettes, even of lower quality).

- Ergonomic loading door: for convenient and easy loading of wood and fractionated fuel (chips, sawdust, etc.) throughout the combustion chamber compartment.

- Bulky loading chamber: combustion can last up to 8 hours. In combination with the embers maintenance system, the boiler can work without turning off for 24 hours before needing a new charging.

- Versatility of installation: right / left version of the door, of the turbulator levers and of the union fittings, adjustable fitting of the fume extractor.

- High technology control unit and sophisticated management program: allow to set the desired combustion power directly in percentage and to regulate the boiler, in continuous operation, from 50% to 130% of the nominal power. The 50% power setting guarantees a long duration of combustion inside the boiler, with an efficiency comparable to that of the nominal power. This solution allows the boiler to work at reduced power and to install an inertial storage tank with a smaller capacity.

- Operation with climatic adjustment and many possibilities of expansion through further mixing circuits, remote boiler panel with room thermostat function, remote management via internet and via App for Smartphone and Tablet

* Sampled at a temperature between 20 and 50 degrees centigrade, referred to the dry gas, and to a volumetric concentration of 02 remaining equal to 13%.

** The data are to be considered indicative, calculated on an energy demand equal to 80W / sqm; variations, even significant ones, can be found in the presence of different energy requirements, due to the specific technical and construction characteristics of the building envelope and the winter air-conditioning system.